Introduction

The agrifood, clothing and automotive industries represent the mainstays of the Italian economy. Agrifood, especially, is one of the sectors that most characterizes the made-in-Italy brand in the world. Proof of this is the data, Italian food and beverage exports will surpass the 60 billion euro mark in 2022 (ISMEA elaborations on ISTAT data).

However, there are two major problems pervading this thriving industry, Italian Sounding and counterfeiting. To date, it is estimated that fake Made in Italy and international piracy have generated about 100 billion euros, a growth of 70 percent in 10 years, to the detriment of the official Italian export segment, which continues to suffer substantial economic damage due to fake Italian.

The country of origin in which a product was manufactured, causes in the consumer the so-called Country of origin effect (COO effect), that is, the belief, positive or negative, that the consumer attributes to a given finished product or service simply because it was made in a given country. Counterfeiting of Italian-made products, therefore, results not only in economic damage but also in significant image damage, due to the marketing of products that are totally inadequate compared to Italian production standards.

In the food industry -complex, crowded and competitive- there are three key factors that must necessarily be taken into account in order to make the most of the sector's underground potential:

1. The need of the new consumer, critical, social, curious, eager for information about the dish and its history;

2. A technology of enormous potential but still little exploited by industry players;

3. The need for certification as an information and assurance tool:

- For the consumer who wants to know and not just rely

- For the producer who wants to place his products in a virtuous process, away from the risks of counterfeiting;

- For the restaurateur who can offer his customers a certified and quality product;

- For the community and institutions whose goal is to enhance and protect Made in Italy;

Industry's problems

There is a large gap within the Italian food industry (and beyond) that prevents consumers, producers and restaurateurs from fully enjoying the benefits associated with Made in Italy products. The gap stems mainly from food counterfeiting and lack of transparency about the processes and origin of the raw materials used to obtain the final product. The report of the Central Inspectorate for Fraud Repression (Icqrf) with details on interventions against fraud, Italian sounding phenomena and counterfeiting to the detriment of made in Italy agri-food products, shows, how, in 2017 alone, 22,000 tons of food products were seized, with a countervalue of about 100 million euros. Fraud also concerns labeling methods, controls carried out by Icqrf in fact reveal that labels lie in 38 percent of cases.

The FoodTech Market

As in all industries, technology plays a key role in development, however, the agribusiness sector has not been able to innovate like other sectors. In fact, according to a study conducted by the McKinsey Global Institute, the agricultural sector appears to be the least digitized compared to major industries.

"Foodtech (or agri food tech) is the emerging sector that aims to explore how technology can be harnessed to improve efficiency and sustainability in food design, production, choice, and delivery" (Forward Fooding, 2019).

Despite the small size of the segment, there have been some very strong signs of growth in recent years that have inevitably increased the interest of entrepreneurs and researchers.

The report "The state of global Foodtech" produced by Talent garden and Forward fooding shows the health and scalability of foodtech through some interesting data:

- 17 billion euros of investments made in 2020, totaling 93 billion euros invested since 2010.

- 10,000 Food Tech startups and companies in the market flanked by 250 accelerators.

- Massive presence of Angel investors, Ventures Capital and institutional funds ready to invest in the sector's new promises.

Blockchain, technology to support the industry

Traceability is a key concept in the agribusiness sector today.

- It represents the ability to trace all the elements that contribute to the realization of the product.

- It is the management and control tool for the agrifood supply chains involved in the marketing process of products on the market, characterized by increasingly complex trade exchanges.

- It is the answer to the growing demands for food safety from authorities and consumers.

- It constitutes the tool for sharing responsibilities among all actors in the supply chain, from the producer to the consumer.

- It supports companies from the point of view of competitiveness and rationalization of production systems.

- It enables the enhancement of quality agrifood production, as it allows the product to be tracked through all stages of production.

Among the technological solutions that enable the development of reliable and incorruptible traceability systems is Blockchain, a technology belonging to the large family of Distributed Ledger Technologies (DLT). Blockchain (or blockchain) is a ledger of information distributed among actors (nodes) in the same network, independent of each other. Each node has a copy of the ledger, and if the approval of the data to be added is successful, each actor in the network will see its ledger automatically updated.

Comparison, Benefits and Limitations

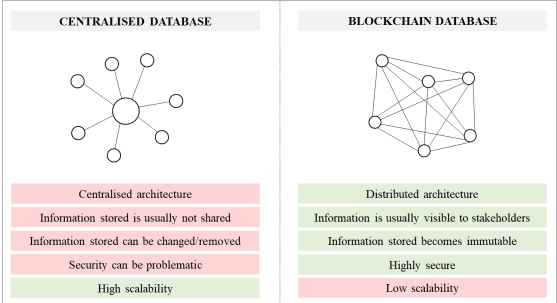

The following image depicts the main differences between a centralized and a decentralized information management approach.

A Triple Helix Approach for the Diffusion of Blockchain Technology against Counterfeiting of Made in Italy Products in SMEs of the Marche Region, Niccolò Testi, 2022.

A Triple Helix Approach for the Diffusion of Blockchain Technology against Counterfeiting of Made in Italy Products in SMEs of the Marche Region, Niccolò Testi, 2022.The centralized approach, applied to food supply chain traceability, entails fragilities about transparency and information security:

1. The information collected is inaccessible to stakeholders (Supply chain partners, authorities, consumers), leading to issues of transparency and trust throughout the chain.

2. Entered information can be easily changed/modified by malicious actors.

3. Security is a weakness (tampering with the one node allows access to the entire registry).

4. Information comes from a single source and is verified by a single centralized actor, which is easily corrupted (high dependency).

In contrast, the decentralized approach brings with it a number of relevant benefits:

1. the ability to share tracked products and their history with all participants in the network, from producer to consumer;

2. before being entered into the registry, the data must be previously approved by a majority of the network participants, thus increasing the security and veracity of the information;

3. once the information has been approved, in order to change or remove it, the malicious party would have to correct a majority of the nodes in the network, a practice that is economically inconvenient;

However, there are still limitations that the Blockchain faces, one of which is scalability. In order to achieve the high standards of security and decentralization that the technology offers, there is a need to employ a large amount of time and computational power to validate transactions, a drag on mass adoption due to energy costs, the capabilities of devices currently on the market, and the data processing speed of current centralized competitors.

Despite this, the technology is continually expanding, and major protocols such as Ethereum's Blockchain appear to have solved the current limitation. Ethereum, by transitioning from the primordial Proof of Work (PoW) consensus mechanism [1] to the current Proof of Stake (PoS) [2], has been able to eliminate the energy-intensive component of its Blockchain and streamline transaction management. By adopting a consensus mechanism based on the immobilization of funds in the form of collateral, network actors are incentivized to act properly and disincentivized to act maliciously, under penalty of seizing the deposited funds. The change in mode, despite countless industry concerns-as Ethereum is one of the busiest networks in the blockchain ecosystem-has occurred correctly, thus taking another step in terms of innovation and efficiency.

[1] The term Proof-of-Work (PoW) refers to the consensus algorithm underlying a blockchain network. This algorithm is used to confirm transactions and produce the new blockchain blocks; the PoW incentivizes miners to compete with each other in processing exchanges, receiving a reward in return. Miners solve the problem, -employing computational power start a new block and confirm all transactions within it.

[2] A type of protocol for securing a blockchain network and achieving distributed consensus is called proof-of-stake (PoS). It is based on the principle that each user is required to prove possession of a certain amount of cryptocurrency, deposit themselves as collateral and act as validators in order to receive a reward for their work. In case a validator acts maliciously, the deposited funds will be taken away from him/her automatically.

Prerequisites for deployment

To fully exploit the potential of digital innovation and Industry 4.0, certain prerequisites must necessarily be met.

1. Expansion of broadband and extra-wideband to rural areas is of paramount importance to ensure supply chain interconnection.

2. Changing the approach: the limited willingness to innovate, coupled with an excessive adherence to traditional business management methods and a low appetite for risk on the part of enterprises, contributes to concealing enormous untapped potential.

3. Preparation of operators is essential; there is a need for substantial investment in training-employees aimed at the digital conversion of processes, without which management would be impractical.

Although Italy is moving toward digital transition, albeit slowly, the spread of Agriculture 4.0 still encounters many obstacles:

- Cultural barriers to innovation;

- Partial awareness of the benefits by farm owners and administrators;

- Inability of farms to invest in and estimate the benefits of innovative technologies such as Blockchain and Internet of Things systems.

Emerging for these reasons is the need to work on farm awareness in order to fully appreciate the potential benefits of these technologies.

Conclusion

Made in Italy is a valuable asset that should be preserved with extreme care.

However, in order for the new paradigm to become an integral part of the industry, it is of paramount importance to incentivize user-friendly innovation in order to facilitate the mass adoption and diffusion of Blockchain. As noted above, the potential benefits of the technology are multiple and cross-cutting. Currently, visionary users who have embraced and deployed this revolution fertilize not only the food sector but also a variety of sectors of the international socioeconomic organization. Small companies, multinational corporations and government institutions have experienced, thanks to the use of Blockchain, significant improvements in terms of business process efficiency and greater transparency and traceability of information. It is up to us to spread the founding principles of this technology and promote the benefits of its appropriate use, which in the long run will enable a more intimate and deeper collaboration between individuals and society.

"Because collaboration is stronger than competition." (G.L. Comandini, 2020, From Zero to the Moon).